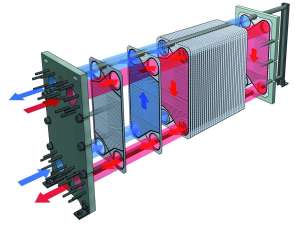

I used a lot of plate heat exhangers in my plant and most of them are manufactured by Schmidt-Bretten. The model/type of plate heat exchanger that i used is Sigma 64. Just like the one that you can see on my previous post, but that one is fouling badly. You can see the pieces of hard gum and scale etc ugly stuff....

I'm having a tough time gathering informations and

inventory of my spare heat exchanger plates. I need to back up my plates so that i can dismantle a heat exchanger and replace them immedietly with the spare plates come with gasket. This is very important to ensure production smoothness. Well, there's a lot to tell about a small topic of heat exchanger. We do not get this in university and text book. We get most of this from experience.

Following are some information that i took from Schmidt-Bretten site.

The main advantages of plate heat exchangers are * High heat transfer coefficient with low surface areas. * Compact design, does not need much space. * Small temperature differences are possible between the fluids. * High versatility, the design allows for fast and easy rearranging of the plates as operating or process conditions change. * Movable pressure plates allow easy access to the plates for cleaning. * Low investment costs. * High corrosion resistance. * A plate exchanger contains only low quantities of fluids. * Material for plates and gaskets is chosen according to end use. * Easy-to-service.

Read more from Schmidt-Bretten Link Here

Subscribe to this blog to get updated with various chemical engineering experience info/sharing...subscribe link on the side bar

Judul : Schmidt-Bretten Plate Heat Exchanger

Deskripsi : I used a lot of plate heat exhangers in my plant and most of them are manufactured by Schmidt-Bretten. The model/type of plate heat exchange...

keyword :

Schmidt-Bretten Plate Heat Exchanger,

Heat Exchanger